Shipbuilding Case Study Tiger Ceramic Allows a Shipbuilder to Meet Back Gouge Standards While Delivering $20K Savings

Challenge: Steel Back Gouge Standards Must Be Met for Ship Welding

A United States shipbuilder that specializes in the commercial and defense aluminum vessel market had recently expanded its production to include steel ships. The Welding Engineer charged with leading the expansion faced a challenge that threatened the company’s ability to deliver steel ships to government specifications. According to the Navy Back gouge standard – Mil Standard 1689A, structures that are welded on both sides must be back gouged to sound metal to ensure full penetration of a weld. In this process, back gouging on aluminum is done with carbide blades, however, they are not an effective option on steel. Having no standard operating procedures in place or previous experience testing abrasives the Welding Engineer needed to find an abrasive product that worked on steel. Without a solution, they would not be able to fulfill their current contracts and run the risk of not winning future bids.

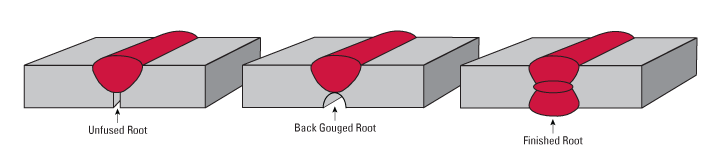

Back gouging procedures are implemented during the shipbuilding process where it is not possible to guarantee the consistency of a weld root. This can occur for several reasons but is primarily where the machining of an accurate weld preparation is not economically viable or practical.

Solution:

To address this urgent need, Weiler brought in a team of experts that included the local District Sales Manager, Abrasive Specialist, and Product Category Manager. After reviewing the application during an on-site visit, the team recommended an 1/8 inch bonded combination wheel as the best solution for steel back gouging. To select the best wheel for the application, several options were brought in for testing.

Throughout testing, the Weiler Consumable Productivity process was leveraged to accurately measure cut rate, wheel life, and labor costs. This provided the Welding Engineer with hard data to select the wheel that offered the best productivity and total cost. “I don’t want to base any of this on my opinion.”

Result:

Through collaboration, comprehensive testing, and evaluation it was proven that the Tiger Ceramic 1/8 combination wheel was the best solution, delivering an annual savings of $20,000 over the other wheels tested. The Weiler team delivered an SOP to the Welding Engineer for future testing and most importantly solved a production-halting application challenge that threatened current and future business, allowing the shipbuilder to meet customer demands.

“Nobody captures and optimizes grinding costs in shipyard welding, like Weiler.”

- Welding Engineer

$20,000

Related Resources

Schedule an On-Site Assessment

Don't let inefficiency, safety issues, or labor shortages hold your metal fabrication business back. Contact us today to learn more about how our abrasives for metal can help you achieve a smooth finish, prioritize safety, and address labor shortages with efficient and safe grinding solutions.