Maximize Your Foundry's Efficiency at Cast Expo

Eliminate bottlenecks and boost profitability with Weiler Abrasives. Visit us at Booth #2613, Atlanta, GA.

Join us at Cast Expo, booth #2613, and learn how to increase your production efficiency and improve profitability – all while meeting your customer's expectations.

Can't attend the show?

Contact us today to learn how Weiler can help you overcome your surface conditioning challenges and enhance your operations.

Date: April 12 - 15, 2025

Location: Atlanta, GA

Venue: Georgia World Congress Center

Booth: #2613

Website: CastExpo Website

Weiler Consumable Productivity

Weiler's Consumable Productivity (WCP) program offers a streamlined approach to uncovering cost and time savings in fabrication operations, even without in-house resources for data analysis. Implemented by Weiler's abrasive experts, WCP utilizes a proven process to measure real-world data with minimal disruption to your facility. Through a simple evaluation of your operations and abrasive usage, the program identifies key areas for improvement, optimizing efficiency, and reducing expenses.

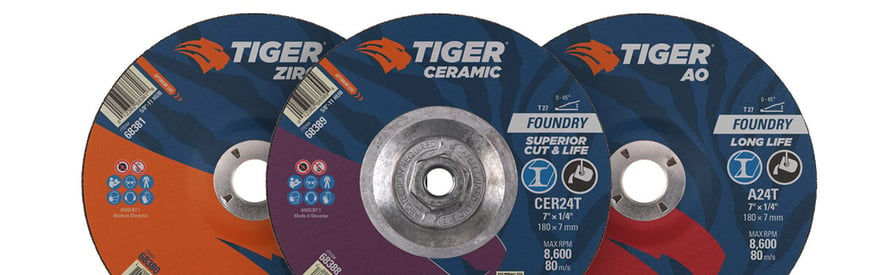

Type 27 Grinding Wheels

Tiger Ceramic Type 27 grinding wheels are designed for demanding foundry applications, providing exceptional cutting performance and extended lifespan. They remove up to 40% more material than zirconia wheels, boosting uptime and reducing replacements. An advanced anti-chipping technology enhances operator safety by minimizing debris and ensuring a reliable grinding edge, while triple fiberglass reinforcement strengthens the wheel. Available in zirconia and aluminum oxide, the ceramic option sets the highest performance standard.

Type 11 Flaring Cup Grinding Wheels

Weiler Abrasives' Tiger Ceramic cup grinding wheels, featuring an exclusive ceramic grain, offer 30% faster cutting than zirconia alternatives, enhancing productivity on hard materials. A balanced design reduces vibration, while an anchored hexagon nut ensures safety and resists breakage. Available in zirconia, silicon carbide, and aluminum oxide, Tiger cups cater to diverse foundry needs.

Cones & Plugs

For use with straight grinders, Tiger cones and plugs provide an aggressive cut-rate from start to finish. They are ideal for ID cleaning, hole edge beveling, cleaning castings in hard-to-reach areas. Each cone and plug feature an anchored, heavy-duty steel hex nut to secure the abrasives to the grinder and improve operator safety.

Snagging Wheels

Tiger Type 1 snagging wheels, available in various sizes with double fiberglass reinforcement, excel in heavy stock removal and rough beveling for pneumatic and electric grinders. Weiler Abrasives' foundry lineup, including Tiger Ceramic, Zirc, and AO, offers cones, plugs, and snagging wheels designed for smooth, vibration-free operation and aggressive cutting, enhancing operator comfort and productivity.

Mounted Points

Ideal for cleaning IDs, complex geometries, hard-to-reach places and more, Tiger Zirc mounted points are available in a variety of shapes. They feature an engineered stem bonding for strength, stability and safety and have a dressed work surface, so operators don’t need to break them in.

Case Studies

At Weiler, it’s our mission is to be the best partner to our customers every day. Here are a few examples of how we helped customers in your industry overcome surface conditioning challenges.