Cleaning

Abrasive Cleaning Solutions: The Complete Guide to Surface Preparation and Maintenance

In industrial and fabrication settings, cleaning is the process of removing unwanted materials such as rust, scale, coatings, and debris from surfaces and components. This essential step optimizes materials and equipment for further processing, improves product performance, and extends equipment lifespan.

Proper cleaning represents a critical foundation for surface preparation and expedites the adhesion of paints, coatings, and welds. It also contributes to equipment longevity by preventing damage caused by corrosion, buildup, or contaminants. Furthermore, efficient cleaning practices lead to overall increased productivity, reduced downtime, and streamlined operations.

At Weiler Abrasives, we understand the importance of reliable and effective cleaning solutions. With a commitment to innovation and quality, we provide a wide range of discs designed to address diverse cleaning challenges across industries. From rust removal to surface preparation, Weiler’s products empower you to achieve consistent and efficient results.

The Importance of Power Brush and Abrasive Cleaning

Cleaning plays a vital role in a variety of industrial and fabrication processes. Key applications and benefits include:

- Surface Preparation for Better Results: Cleaning prepares surfaces for painting, coating, or welding. This process removes dirt, grease, and other contaminants that could compromise the quality of finishes and results in longer-lasting and more durable equipment.

- Removal of Rust and Corrosion for Increased Longevity: Cleaning eliminates rust, mill scale, and corrosive elements, restoring the structural integrity of materials. Cleaning not only extends the lifespan of components but also enhances their appearance and reliability.

- Maintenance of Equipment and Facilities for Improved Performance: Regular cleaning of machinery, tools, and facilities prevents the buildup of harmful residues, reduces wear and tear, and minimizes the risk of unexpected failures. Proper maintenance leads to smoother operations and lower long-term costs.

Key Challenges of Abrasive Cleaning Operations

Abrasive cleaning is a vital process, but it comes with its share of challenges that require strategic solutions.

- Tough-to-Remove Materials: Rust, hardened coatings, and stubborn contaminants often require highly durable abrasives and specific techniques for effective removal.

- Achieving Balance: Overly aggressive brushes can damage surfaces, while insufficient abrasiveness can lead to incomplete cleaning, compromising downstream processes.

- Minimizing Downtime: Cleaning operations may interrupt workflows. Selecting high-performance tools that optimize efficiency reduces downtime and boosts productivity.

- Operator Fatigue and Safety Risks: Using abrasives and brushes beyond normal product life can lead to operator fatigue and increase the risk of accidents. Ergonomic designs and proper training are essential for safe and efficient operations.

- Cross-Contamination Risks: Using discs contaminated with debris or residue, such as steel particles, can deteriorate the material being cleaned. For example, power brushes used on one steel may transfer contaminants that affect the quality of a stainless steel surface.

- Compromise of Weld Strength: All mill scale, grease, oil, dirt, paint, or other surface contaminants must be removed prior to welding. Failure to do so can generate hydrogen gas or interfere with weld fusion, leading to weakened welds and potential structural failures.

Addressing these challenges with the right discs, techniques, and practices leads to high-quality results through consistent cleaning solutions.

Selecting the Right Cleaning Discs

Several factors should guide your selection process to choosing the best cleaning discs:

Factors to Consider

- Material Type: Some materials require tailored discs for effective cleaning without damage. For instance, steel surfaces may benefit from aggressive abrasives, while softer materials like aluminum may require less aggressive options to prevent surface deterioration.

- Surface Size: Consider the size of the surface area to be cleaned. Larger surfaces may need power tools with wider brushes or discs for efficiency, while smaller or intricate areas may benefit from hand brushes or precision tools for greater control.

- Surface Finish Requirements: Determine the desired finish before selecting abrasives. Coarse abrasives may be suitable for heavy-duty rust removal, while finer abrasives deliver smoother surfaces for coating or welding preparation.

- Desired Level of Abrasiveness: Match the grit level of the abrasive to the cleaning task. Lower grit levels provide more aggressive cleaning, while higher grit levels offer greater precision and control for delicate applications.

- Compatibility with Existing Equipment: Check that the discs integrate seamlessly with your current equipment setup. This includes hand brushes for manual tasks and power tools such as right-angle grinders, bench grinders, CNC machines, die grinders, and mini die grinders for more advanced operations.

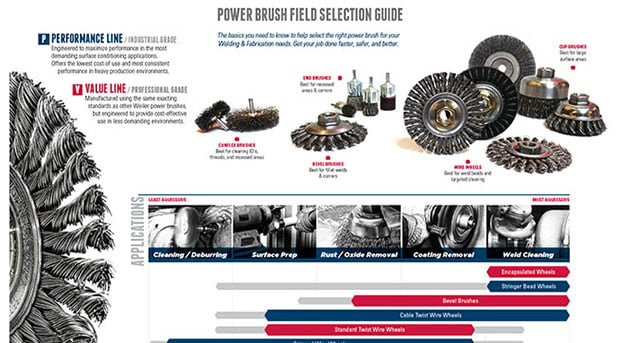

Overview of Abrasive Cleaning Products

Cup Brushes

Cup Brushes

Ideal for cleaning larger, flat surfaces, removing rust, and stripping paint efficiently.

Wheel Brushes

Wheel Brushes

Perfect for edge cleaning, weld preparation, and removing surface contaminants.

End Brushes

End Brushes

Ideal for cleaning applications in corners and hard-to-reach areas.

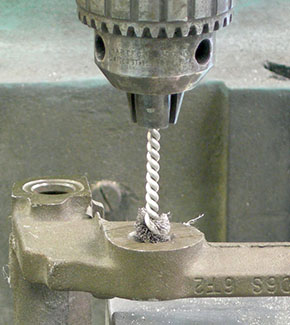

Tube Brushes

Tube Brushes

Designed for precision cleaning in tight spaces, such as tubes or holes.Crimped Wire

Crimped Wire

Flexible and suitable for light-to-medium cleaning tasks.Knot Wire

Knot Wire

More aggressive and designed for heavy-duty applications requiring deep cleaning and material removal.Abrasive Pads and Discs

Abrasive pads and discs offer flexibility and efficiency for a range of cleaning needs:

- Coated Abrasives Like Resin Fiber Discs and Flap Discs: Excellent for blending, smoothing, and finishing surfaces. They combine cutting power with the ability to create a refined finish.

- Non-woven Abrasives Such as Strip Discs and Surface Conditioning Wheels: Provide controlled material removal and create uniform finishes, ideal for surface preparation tasks.

Hand Tools for Precision Cleaning

Manual brushes are indispensable for precision cleaning and smaller-scale tasks:

- Hand Brushes: These tools allow operators to focus on detailed areas, offering control and flexibility for hard-to-reach spots or delicate surfaces.

Best Practices for Safe and Efficient Cleaning

Safety Guidelines

Proper Use of Personal Protective Equipment (PPE)

Because safety starts with preparation, it’s important to always wear the appropriate PPE when performing cleaning tasks. PPE includes gloves to protect your hands from sharp edges or abrasive surfaces, goggles to shield your eyes from flying debris, and any additional protective gear specific to the task at hand.

Using the Right Abrasive for the Job

Confirm that the abrasive you select is appropriate for the task at hand by considering its RPM rating and compatibility with the material being cleaned. Verify that the tool's speed, pressure, and orientation are optimal for the job, and maintain a steady, light touch to avoid excessive wear on discs or brushes.

Regular Inspection and Maintenance

Inspect wire brushes and abrasive discs for wear or damage before every use. Replace worn-out discs immediately to avoid compromising performance and safety. Routine maintenance of your discs increases their longevity and reduces the risk of accidents.

Elevate Your Safety Game with S.P.O.T. Safety

Enhance workplace safety and productivity with Weiler Abrasives' S.P.O.T. Safety Program. Access tools, training, and resources designed to keep your team protected while achieving superior performance.

Efficiency Tips

Tool Performance Capabilities

The power and speed of your disc significantly affect cleaning efficiency. For electric tools, higher amperage helps maintain consistent RPMs, so the brush can operate at its best. Proper air pressure is critical for air tools—too low, and the tool will underperform. Make sure to use the correct extension cord length and gauge to deliver adequate power for electric tools and regularly check air pressure for pneumatic tools.

Pressure and Technique Matter

When using wire brushes, it’s important to let the wire tips do the cleaning. Excessive pressure can cause wire breakage and reduce the brush's effectiveness. Use a light, controlled touch and position the brush so only the tips make contact with the surface. For finer cleaning tasks, opt for thinner wire gauges, which offer more cleaning points and greater efficiency.

Maintaining Brush Performance

To keep brushes effective, rotate them periodically. Rotation ensures the wire tips remain sharp and maximizes the brush’s cutting ability. Using brushes designed for easy rotation can make this process quicker and more convenient.

Monitoring Brush Condition

As brushes wear, their cleaning capability diminishes. Reduced diameter or visible wire breakage can negatively impact performance and safety. Replace worn brushes promptly to gain optimal results and maintain a safe operation.

Proper Storage for Longevity

Storing discs and brushes in a clean, dry environment helps preserve their condition. Remove brushes from tools when not in use, and store them in their original packaging to protect the wire tips. Proper storage extends the life of your brushes and supports consistent cleaning results.

Industries and Applications for Abrasive Cleaning

Cleaning applications and techniques vary across industries, and it is essential to select the correct products to tackle industry-specific challenges effectively.

Abrasive cleaning is a versatile and essential process in various industries, enabling efficient removal of contaminants, preparation for coatings, and restoration of surfaces. Below are specific applications of abrasive cleaning across key industries:

- Metal Fabrication and Pipeline: Abrasive cleaning is critical in metal fabrication and pipeline maintenance to remove rust, mill scale, weld spatter, and other contaminants. For example, pipe weld joints are cleaned to ensure proper fusion and coatings, and fabricated components are prepared for painting or powder coating. Abrasive cleaning enhances the longevity and performance of metal structures, ensuring compliance with industry standards.

- Automotive and Aerospace: In the automotive and aerospace industries, abrasive cleaning plays a vital role in maintaining high standards of safety and precision. Applications include removing old paint or coatings from car bodies, aircraft panels, and engine components to prepare surfaces for repainting or repair. Additionally, abrasive cleaning ensures surfaces are free from contaminants like oil and grease, facilitating better adhesion during assembly or refurbishment.

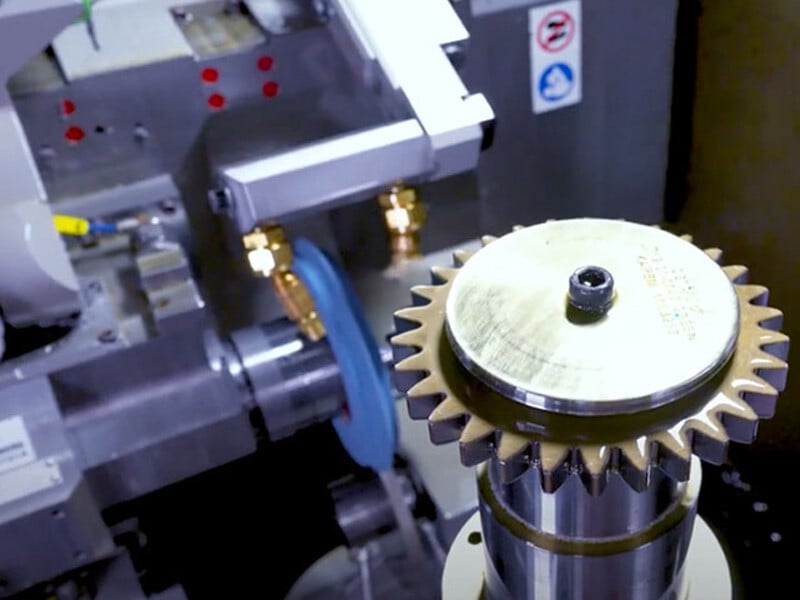

- MRO (Maintenance, Repair, and Operations): Abrasive cleaning is indispensable for MRO teams tasked with maintaining machinery and equipment. This includes cleaning worn machine parts, removing corrosion from fasteners and tools, and refurbishing equipment surfaces to restore optimal functionality. Abrasives are also used for surface preparation before reapplying lubricants, protective coatings, or repairs.

- Construction: In the construction industry, abrasive cleaning ensures the durability and appearance of various surfaces. Concrete and masonry surfaces are cleaned to remove dirt, old coatings, or graffiti, while metal rebar is cleaned to eliminate corrosion before being embedded in concrete. Structural steel components are prepared for welding, coating, or painting using abrasive cleaning processes.

- Energy and Power Generation: Energy facilities such as power plants and wind farms rely on abrasive cleaning to maintain equipment efficiency and safety. Applications include cleaning turbine blades, boiler interiors, and heat exchanger surfaces to remove scale, corrosion, and other deposits. In renewable energy, abrasive cleaning is used for surface preparation of wind turbine towers and blades, ensuring long-term performance in harsh environments.

- Shipbuilding and Marine: The marine environment presents unique challenges, such as saltwater corrosion and biofouling. Abrasive cleaning is used extensively in shipbuilding and maintenance to remove rust, marine growth, and old coatings from hulls, decks, and tanks. It also prepares metal surfaces for protective coatings that safeguard vessels from corrosion, extending their service life.

Why Weiler for Abrasive Cleaning Solutions?

Innovation Driving Performance

Weiler takes innovation beyond product creation, focusing on delivering complete solutions for operational excellence. The Weiler Consumable Productivity (WCP) program reflects this commitment by combining industry-leading technical expertise with practical application insights. WCP provides customers with customized strategies to streamline their abrasive processes, uncover cost-saving opportunities, and enhance overall quality.

Quality That Delivers Results

Weiler’s dedication to excellence is rooted in advanced manufacturing techniques and upheld by thorough testing and quality control protocols. Our products are carefully evaluated to guarantee it exceeds industry standards for safety and performance. This focus on quality enables customers to maintain high production standards while enhancing operational productivity and reliability.

Read More About our History and Expertise

Technical Support: Expertise When You Need It

Weiler’s technical support is designed to provide more than just product guidance—it delivers end-to-end application support. With on-site process evaluations, we help customers unlock the full potential of their abrasive operations. Comprehensive training programs ensure operators are skilled in proper techniques and safety protocols. To promote consistency, we also offer documentation support, helping streamline performance across teams and shifts.

- New innovations help you meet environmental standards and sustainability expectations

- World-class research, development, and manufacturing capabilities keep your business ahead of the competition

- Proprietary technologies and global access to abrasive cutting wheels provide flexibility and freedom to develop limitless solutions

- Stable supply and local inventory to keep your business running smoothly and reduce your inventory burden

- On-site technical support and education to keep your cutting process optimized and your people safe

- Engineered solutions tailored to your specific applications

Our Customers Experience Unparalleled Results

“I just don’t want to be a gear supplier. I want to be a partner. And I think Weiler has done a good job of doing that with Rave.”

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Related Resources

Discover how a contractor improved safety, boosted efficiency, and achieved 29% longer wheel life with Weiler Abrasives' Tiger Pipeline Wheel.

See how a manufacturing company reduced costs by 15% and simplified its operations through Weiler Abrasives’ innovative conversion approach.

Discover how Weiler Abrasives' expertise helped a foundry increase throughput by 53% in their cleaning room operations.

Abrasive Cleaning Resources

Guide

Unlock expert insights and practical tips in this comprehensive guide to selecting and using wire brushes effectively for optimal cleaning, surface preparation, and finishing results.

Catalog

Review our complete catalog of high-performance metal fabrication solutions, featuring discs and accessories designed to deliver exceptional results for any project.

Brochure

Learn how Weiler Abrasives' specialized pipeline abrasives, including Roughneck® Stringer Bead Brushes and Tiger® Flap Discs, help professionals tackle the toughest pipeline challenges.

Let’s Revolutionize Your Cleaning Operations

Are you ready to take your cleaning processes to the next level with unmatched efficiency, performance, and precision? At Weiler Abrasives, we understand that every operation has unique challenges, and that’s why we’re committed to providing high-performance products designed to meet your specific needs. Our team of experts is here to guide you in selecting the right abrasive cleaning discs and brushes, ensuring optimal results for your industry and application.

Whether you’re looking to remove tough contaminants, prepare surfaces for coatings, or maintain equipment reliability, our high-performance products deliver consistent, reliable outcomes. Our customers gain the abrasives and knowledge to achieve lasting improvements in performance and efficiency.

Reach out to us today to discuss your cleaning challenges. Discover how Weiler abrasives can revolutionize your operations, saving you time, reducing costs, and improving overall productivity.