Success Story:

Top European Stainless Steel Champion Achieves the Impossible

The Challenge

When we approached a market leader in the European cold-rolled stainless-steel industry, they had critical productivity challenges:

G-ratio

G-ratio

Significantly higher G-ratio to improve productivity

Surface Finish

Surface Finish

Superior surface finish quality, particularly on rougher forged rolls

G-ratio

G-ratio

Significantly higher G-ratio to improve productivity

Surface Finish

Surface Finish

Superior surface finish quality, particularly on rougher forged rollsTheir existing grinding wheels delivered suboptimal performance. They needed a solution.

The Data-Driven Solution

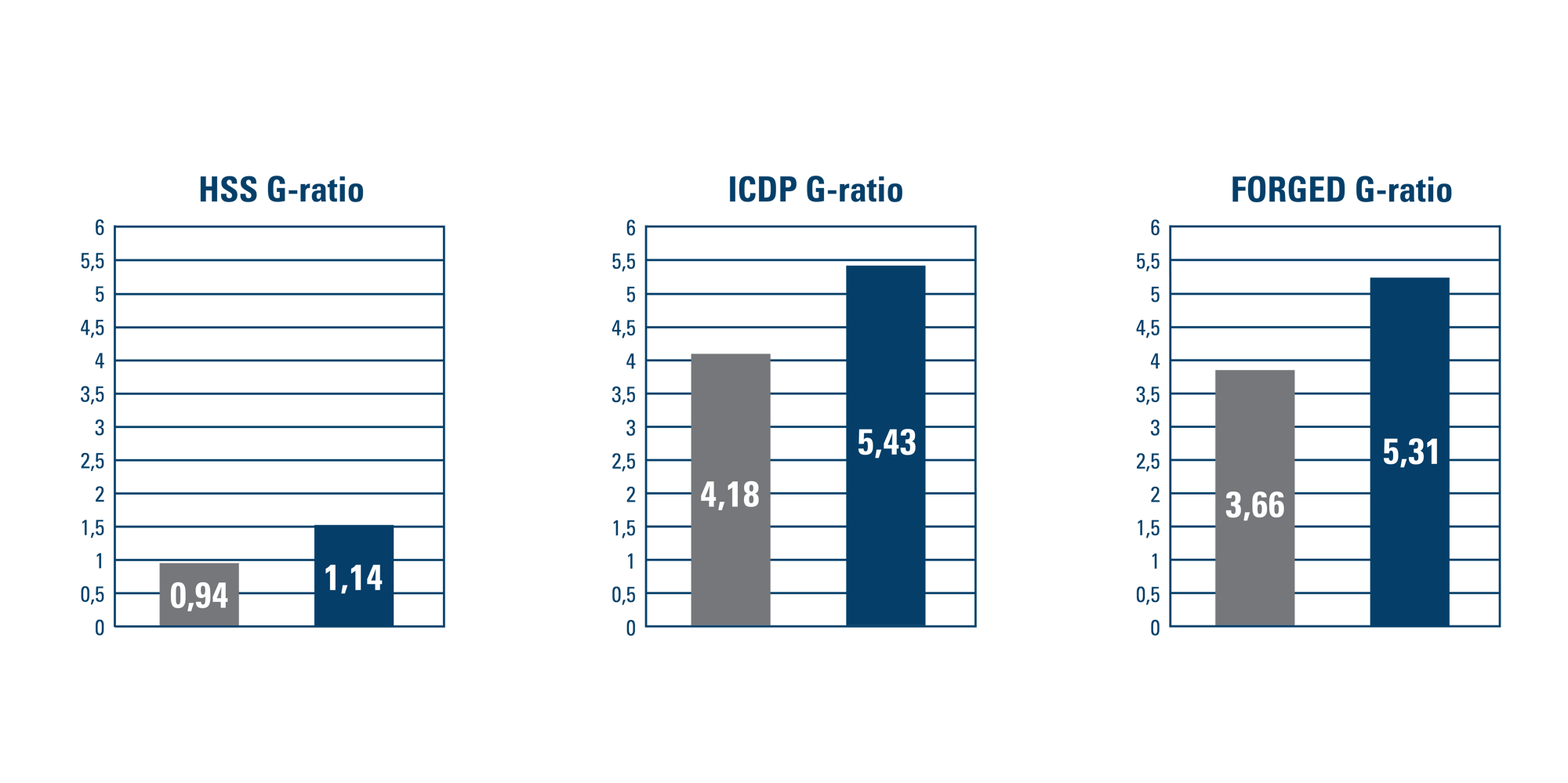

After comprehensively analyzing the specific requirements, we developed our innovative Fortis Mill grinding wheel technology. On-site testing produced remarkable results:

21

%

HSS G-Ratio

30

%

ICDP Material (G-ratio)

24

%

Forged Material (G-ratio)

Targets Achieved

- Superior G-ratio performance across all material types

- Improved surface finish quality in fewer passes

- Multi-material versatility with one solution

- Elimination of quality issues such as chatter marks and burning

The Weiler Advantage

Precise Surface Finish

Ability to achieve specific roughness requirements, whether a smoother or rougher finish is needed

Multi-Material Performance

Allowing one wheel to effectively grind HSS, ICDP, and forged steel

Productivity Improvements

Dramatic productivity improvements with G-ratios up to 3X higher than competitive options

Reduced Downtime

Reduced downtime from fewer wheel changes when processing different materials

Rapid Implementation and Adoption

Just 30 days after implementation, the end-user confirmed successful operation with positive operator feedback and adopted our solution, placing additional orders for the new grinding technology.