Cutting

Schedule an On-site Assessment

The first step to cutting through barriers is to schedule a free on-site assessment where Weiler experts will evaluate how our abrasives can help eliminate inefficiencies, safety issues, and labor shortages in your operation.

Our Approach To Improvement:

- On-Site Assessment

- Test Abrasives

- Measure Results

- Present Documented Cost & Time Savings

- The 5th list item that is medium length

Cutting wheels that deliver precision and performance

Metal cut off wheels designed for demanding industrial applications

Our selection of high-quality cutting wheels optimize cut-rate, durability, and consistency for performance you can count on. From 1mm UltraCut metal cut off wheels that deliver lightning-fast clean cuts to high-speed saw cutting wheels for demanding rail cutting jobs, we have a wide range of cutting wheels to get the job done right.

Industries That Use Our Portable Cutting Wheels

Cutting wheels are vital to productivity and profitability, especially in large-scale metal fabrication operations. At Weiler Abrasives, we make cut-off wheels that deliver results for the most demanding jobs on the toughest metals.

Our cut-off wheels offer incredible versatility. In our extensive selection, you will find cutting wheels tailored to these challenging industries and applications:

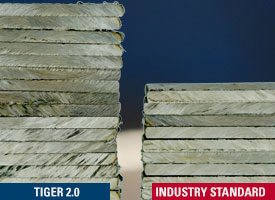

Introducing Tiger 2.0, an evolution in abrasives

Tiger 2.0 sets a new standard in cutting wheel performance. This line of wheels, offers industry-leading cut rates and up to 40% longer wheel life, saving you time and money. The first to market, patent-pending Optimum Use Line provides a visual indicator to ensure operators are using the wheel to its full life, while a QR code provides access to crucial safety information right when you need it. These wheels increase efficiency by as much as 3X, helping professionals do their best work.

Product Innovations

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

SOLID CORE technology

UltraCut is the ultimate angle grinder cutting wheel for precision AND long life. Proprietary SOLID CORE technology increases density of the wheels for longer wheel life, reduced friction, and superior stability while the 1 mm thickness delivers precise cuts.

Longer Life

Tiger 2.0 cut off wheels for metal now last up to 40% longer without sacrificing cut-rate, resulting in fewer change-overs and more cuts over the life of the wheel.

Single Center Reinforcement

A single layer of fiberglass reinforcement in the center of the wheel provides ultra-fast cutting speed and reduces burrs for chop saws.

Cutting

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.