SUCCESS STORY

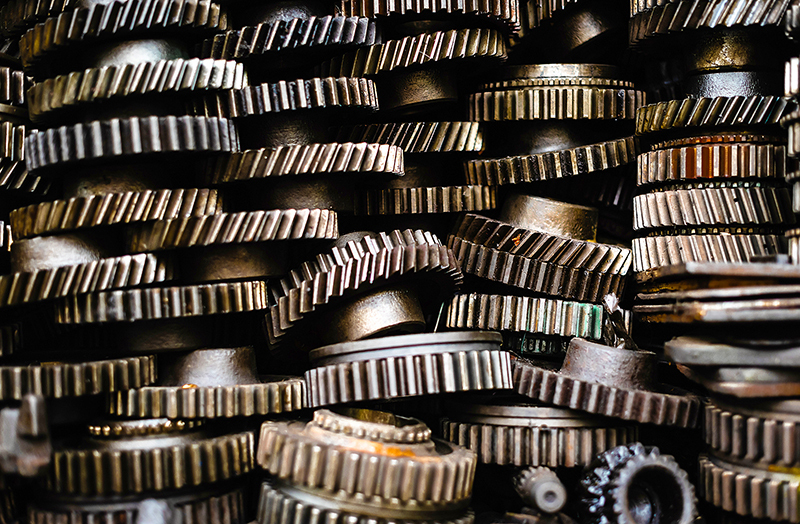

PRECISION UNDER PRESSURE: HOW WE REVOLUTIONIZED AN EAST COAST GEAR BUSINESS

THE PRESSURE OF DOWNTIME

The Challenge

Absence of Support

Absence of Support

No on-site support for years

Vague Technical Direction

Vague Technical Direction

On wheel selection for specific applications

Crushing Lead Times

Crushing Lead Times

16+ weeks for custom orders

Inconsistent Performance

Inconsistent Performance

Erratic results during critical jobs

Absence of Support

Absence of Support

No on-site support for years

Vague Technical Direction

Vague Technical Direction

On wheel selection for specific applications

Crushing Lead Times

Crushing Lead Times

16+ weeks for custom orders

Inconsistent Performance

Inconsistent Performance

Erratic results during critical jobs

DELIVERY IN RECORD TIME

What normally takes 18 months, we delivered in just weeks. This is custom, on-demand wheel delivery to match your needs immediately.

The Solution

- 30% efficiency boost — 8+ hours saved per part

- 50% fewer interruptions — Eliminated wheel adjustments

- Zero guesswork — Technical documentation for every solution

- Superior performance Significant time and cost reduction

A Global Abrasives Partner Focused on Mutual Success

At Weiler Abrasives, our experience dates back to 1898 when Joseph E. Weiler began manufacturing brushes for the jewelry industry in Pforzheim, Germany. Since then, we’ve grown and evolved into a global manufacturer serving customers in over 80 countries with nearly 1,500 employees around the world.

“While the company has grown and expanded significantly since those humble beginnings, our commitment to developing long-term partnerships with customers, co-workers, and community hasn’t changed. We like to call that our 3C’s.” Chris Weiler, Executive Chairman.

Whether you are looking to improve your surface conditioning processes, optimize your consumable spend, or train your team on the safe and proper use of abrasives and brushes, Weiler has the people and expertise to help you achieve your goals.

Weiler: Your Competitive Edge

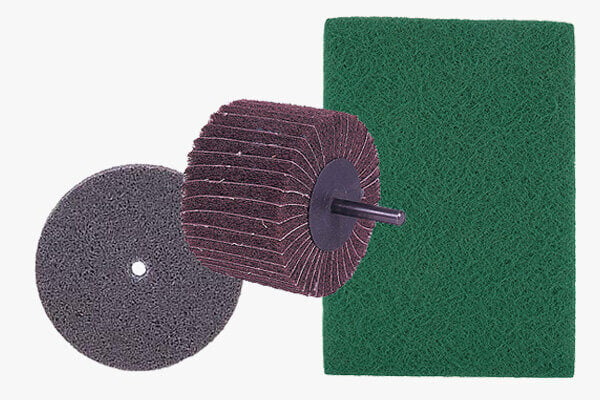

Product Innovations

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Cut Back

PTiger Type 27 grinding wheels are designed with fiberglass cut back from the edge for aggressive grinding right out of the box.

Longer Life

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Our new metal grinding and cut off wheels are designed to be more than just a better product. They were created to help you do your best work.

Our new foundry line delivers a superior combination of life and cut-rate for maximum productivity.

These flap discs offer a paired flap design that delivers high performance grinding on aluminum.

The Impact

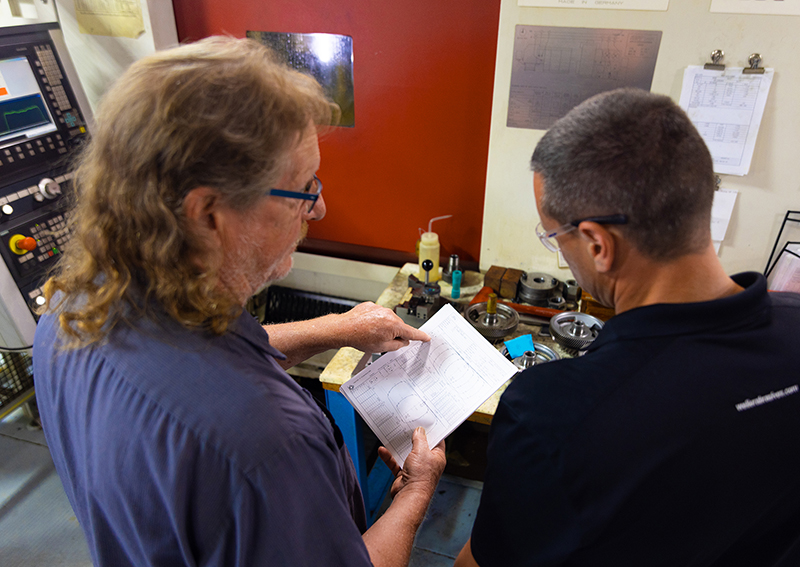

Accelerated Solution

We shipped a custom-profiled wheel within weeks—a timeline that stunned the customer

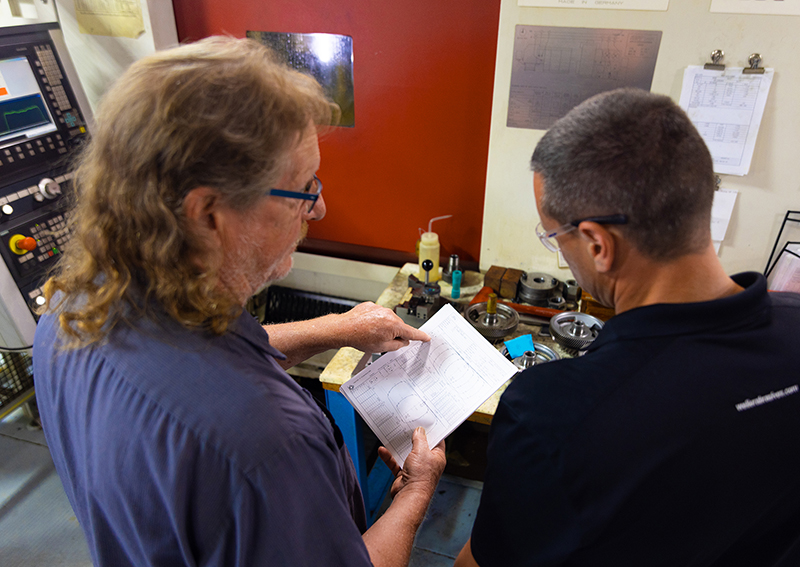

On-Site Partnership

On-site analysis and collaboration led to a custom-designed grinding program calibrated to their exact applications.

Expertise On Demand

A machine error struck— we delivered instant remote support and solution with zero downtime.

Real Innovation

Our custom grinding wheel design delivered performance that slashed cycle times from 28 to 16 hours.

The Critical Difference

With new equipment recently purchased and 24/7 operations planned, we unlocked critical capacity fueling explosive growth! We are not just a supplier, but a real partner invested in their success.

When you face the crushing pressure of downtime, standard supplier relationships crumble. True partnerships deliver.

Find out how we go beyond the products.