SUCCESS STORY

TEXAS MANUFACTURER SAVES BIG AND KEEPS ITS PROMISE!

Deep in the Lone Star state, a premier manufacturer of heavy-duty truck accessories built their reputation on one unshakable principle: protecting families on the road.Operating two fabrication facilities, they process over 40,000 pounds of steel every day. With their commitment to near-zero rejection rates and a reputation for unmatched durability, they needed grinding performance that could match their standards.

The Challenge

Disc Loading

Disc Loading

Used four discs to complete what should have taken two.

Inconsistent Quality

Inconsistent Quality

Uneven scuff pattern left the finish unfinished.

Improper Approach

Improper Approach

Incorrect tools and techniques led to waste.

Lost Productivity

Lost Productivity

Every minute spent troubleshooting was a minute not building.

Disc Loading

Disc Loading

Used four discs to complete what should have taken two.

Inconsistent Quality

Inconsistent Quality

Uneven scuff pattern left the finish unfinished.

Improper Approach

Improper Approach

Incorrect tools and techniques led to waste.

Lost Productivity

Lost Productivity

Every minute spent troubleshooting was a minute not building.

Our Solution

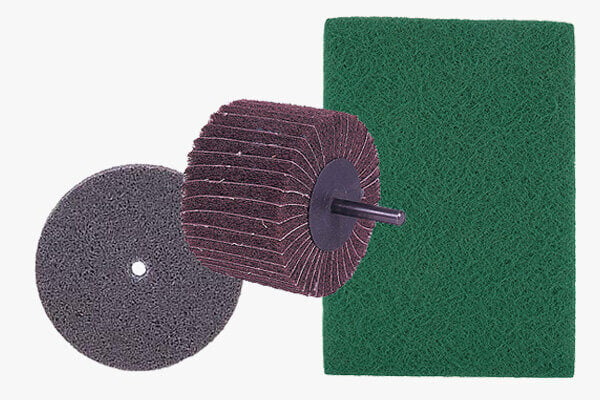

We introduced our new 3D MAX Ceramic Resin Fiber Disc, along with several operational improvements. We advised on the correct backing pad for optimal disc performance, enhanced process efficiencies, proper grinding techniques and provided reliable local distribution to keep them in action.

A Global Abrasives Partner Focused on Mutual Success

At Weiler Abrasives, our experience dates back to 1898 when Joseph E. Weiler began manufacturing brushes for the jewelry industry in Pforzheim, Germany. Since then, we’ve grown and evolved into a global manufacturer serving customers in over 80 countries with nearly 1,500 employees around the world.

“While the company has grown and expanded significantly since those humble beginnings, our commitment to developing long-term partnerships with customers, co-workers, and community hasn’t changed. We like to call that our 3C’s.” Chris Weiler, Executive Chairman.

Whether you are looking to improve your surface conditioning processes, optimize your consumable spend, or train your team on the safe and proper use of abrasives and brushes, Weiler has the people and expertise to help you achieve your goals.

Weiler: Your Competitive Edge

Product Innovations

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Cut Back

PTiger Type 27 grinding wheels are designed with fiberglass cut back from the edge for aggressive grinding right out of the box.

Longer Life

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Optimum Use Line

Patent pending Optimum Use Line provides a visual reference to help get the most out of the wheel. Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Our new metal grinding and cut off wheels are designed to be more than just a better product. They were created to help you do your best work.

Our new foundry line delivers a superior combination of life and cut-rate for maximum productivity.

These flap discs offer a paired flap design that delivers high performance grinding on aluminum.

The Impact

Unmatched Grain Retention

Improved product lifecycle slashed abrasive spend.

Unbeatable Performance

3D grain technology made grinding easier and faster.

On-site Collaboration

On-site collaboration unlocked productivity gains.

Unquestionable Results

Delivered a more consistent finish and reduced rework

TOTAL ANNUAL SAVINGS: $53,500.00

If we can help this operation cut abrasive expenses in half, what could we do for yours?